Injection Moulding: These are definitely accustomed to neat very hot molten plastic, enabling it to solidify and flow for shaping.

Although Each individual website was a bit unique in size and layout, our crew intended a method making use of oblique oil-fired heaters which could realize a snug 22˚C temperature over the winter months. Go through the complete scenario review

Such a chiller is configured and not using a tank. Reverse circulation chillers are usually located near the tank storing the heat transfer fluid to promote a positive head tension to make sure the chiller pump is continually primed.

This Web site utilizes cookies to assist us give you the best working experience after you take a look at. Through the use of this Internet site you consent to our use of these cookies. Find out more details on how we use cookies and the way to control them.

Plating via electrolysis and aluminum anodizing equally have to have exceptionally significant temperatures. To guard the equipment and staff, manufacturers use process cooling to attract absent too much warmth.

The significantly less prevalent open up loop industrial chillers Management the temperature of a liquid in an open up tank or sump by continually recirculating it. The liquid is drawn from the tank, pumped throughout the chiller and back to your tank. In industrial water chillers is the usage of h2o cooling as opposed to air cooling. In this case the condenser doesn't amazing the hot refrigerant with ambient air, but makes use of h2o that's cooled by a cooling tower.

Totally free cooling chillers dramatically reduce Electrical power intake and working expenses, assisting to decrease the more info carbon footprint of your company or facility.

Our FC versions are mounted using an built-in totally free cooler, further more increasing your environmental influence by saving more than 60% of Vitality.

Metalworking, Device Instruments and Laser Pressers: Cooling machines to prevent overheating in the course of significant-velocity, superior-temperature functions. They also stabilise the temperature of laser sources for constant efficiency, and cool areas down in metalworking to lessen thermal worry.

Process Fluid Components: Bronze “Y” strainer with 20 mesh chrome steel screen. Pumps are stainless steel centrifugal. Tanks are insulated with shoe box lid, fill port, and degree sight glass. Moveable programs will include a bypass flow valve.

As other industries evolve, so does process cooling. A number of developments are preserving process cooling applicable now and ground breaking for the long run. Here are just a few of the present developments in process cooling.

Process chillers include a chemical compound, identified as a refrigerant. There are several varieties of refrigerant and purposes according to the temperatures expected but they all work on The essential principle of compression and stage-improve from the refrigerant from the liquid to the gasoline and again to a liquid.

Process chillers will often be the mainstay of 24/7 producing, where output downtime check here is often a no go as a result of Value and effect concerned. Aqua chillers are extremely reliable, strong, designed to previous and but competitively priced.

Unique compressor types accomplish diverse efficiencies based upon application and operating situations (entire load, portion load for illustrations). The running temperature from the chiller will likely dictate which type of compressor is used in its design and style.

Brian Bonsall Then & Now!

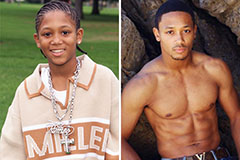

Brian Bonsall Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now!